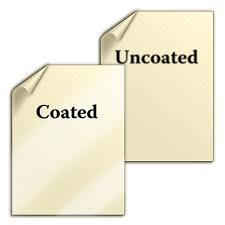

The main reason of coating is to improve the surface quality of paper or board. The excellence improvement can be aimed at optical properties such as brightness, gloss or opacity, at tactile property such as smoothness, but, most importantly, at print-ability and print image value.

The application of (usually white) pigments to the base paper surface enhances the brightness of the paper. In addition, the opacity increases due to the high light scattering of the pigments. This improves the optical appearance, because the shine through of the back side printing is reduced. Also, the coat layer evens out the surface landscape of the sheet, resulting in an improved smoothness, which in turn gives a better gloss.

The application of (usually white) pigments to the base paper surface enhances the brightness of the paper. In addition, the opacity increases due to the high light scattering of the pigments. This improves the optical appearance, because the shine through of the back side printing is reduced. Also, the coat layer evens out the surface landscape of the sheet, resulting in an improved smoothness, which in turn gives a better gloss.

The coat layer reduces the diffusion of ink into the paper sheet. Therefore, the ink does not spread as much and the print image is clear and sharp. The print density and the print gloss are enhanced, and the ink insists is reduced compared to uncoated papers.For specialty papers, the coat layer can have functional properties. Examples are the thermo sensitive layer of thermal papers or the capsule containing coat layer of carbonless papers.

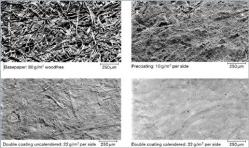

The benefits of applying a coating layer become very apparent when comparing paper surfaces with different coatings. The SEM (scanning electron microscope) micrograph of an 80 gsm wood free base paper shows multiple layers of intersecting fibers. The paper surface is characterized by hills and dales formed by the fiber mesh. The voids between the fibers impair the smoothness and uniformity of the paper surface. The next micrograph shows a percolated paper at the same magnification for comparison.

The SEM (scanning electron microscope) micrograph of an 80 gsm wood free base paper shows multiple layers of intersecting fibers. The paper surface is characterized by hills and dales formed by the fiber mesh. The voids between the fibers impair the smoothness and uniformity of the paper surface. The next micrograph shows a percolated paper at the same magnification for comparison.

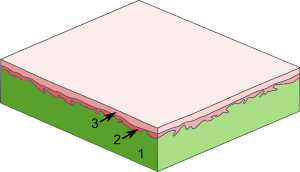

A pre-coating of just 10 gsm per side suffices to cover up the majority of voids and fiber crossings. This helps to smooth and even out the paper surface. Paper surface quality can be further enhanced by the application of a top coat. Coating the paper with another 12 g m–2 per side distinctly enhances the existing pre-coated surface quality, with a number of dominants fiber structures and valleys still remaining visible. Subsequent calendaring achieves an additional quality gain by enhancing smoothness and gloss. The resulting surface is flat, with a minimum of irregularities. An electron microscope picture of a microtome cut from a coated paper sample. In the center of the sheet, the fibers can be seen. The lighter and more densely packed structure on the outside of the paper sheet is the pigments of the coat layers.

A pre-coating of just 10 gsm per side suffices to cover up the majority of voids and fiber crossings. This helps to smooth and even out the paper surface. Paper surface quality can be further enhanced by the application of a top coat. Coating the paper with another 12 g m–2 per side distinctly enhances the existing pre-coated surface quality, with a number of dominants fiber structures and valleys still remaining visible. Subsequent calendaring achieves an additional quality gain by enhancing smoothness and gloss. The resulting surface is flat, with a minimum of irregularities. An electron microscope picture of a microtome cut from a coated paper sample. In the center of the sheet, the fibers can be seen. The lighter and more densely packed structure on the outside of the paper sheet is the pigments of the coat layers.

The caliper of the coat layer varies according to the changing thickness of the base sheet. The surface is smooth so, by coating, paper and board can be upgraded to a higher quality level with added value.

The caliper of the coat layer varies according to the changing thickness of the base sheet. The surface is smooth so, by coating, paper and board can be upgraded to a higher quality level with added value.